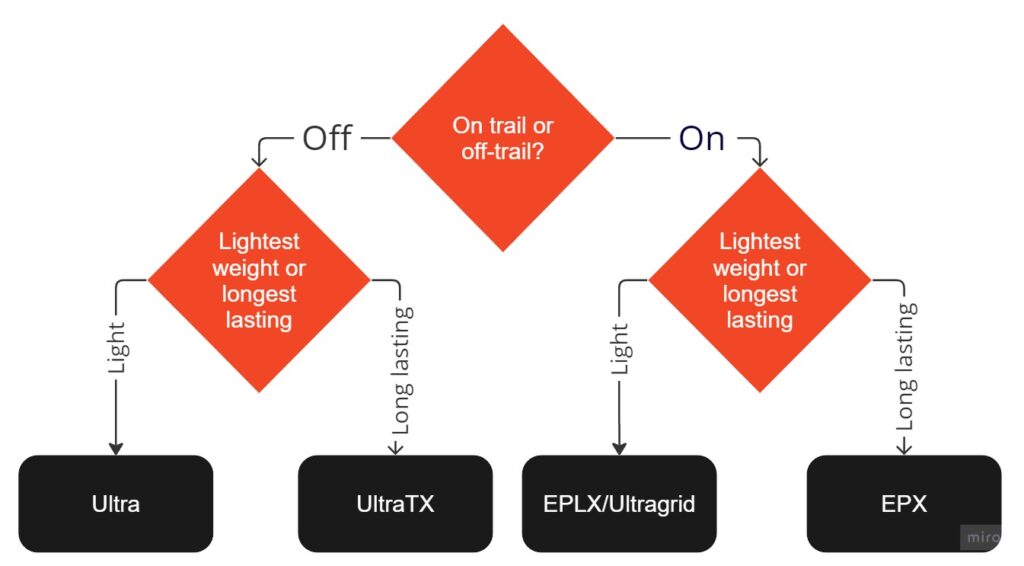

What fabric should you choose?

Here’s the simplest possible flowchart I could make for my recommendations. You can use it based on your priorities. If you want more nuance and specification, read further below.

Main fabrics

I’ve chosen the most suited fabrics for the standard packs. I spend a lot of time testing and evaluating the performance of these fabrics. This means most packs consist of a multitude of different fabrics, suited for different purposes and not just a single fabric for ease of manufacturing. You can read more about the materials if you are putting together a custom pack or simply interested.

EPLX

A stable and light all-polyester waterproof fabric

200 denier polyester face, 45° polyester Cross-ply and waterproof 0,5mm polyester RUV-film.

Polyester components are 100% recycled.

Weight: 146 gsm

Abrasion: 500 cycles

Tear strength: 459 N warp/592 N weft

Waterproof

EPX

Solid 3-layer fabric with long waterproof lifespan made from 100% recycled components.

C0 DWR, 200 denier polyester face with 45° Cross-ply, and 70 denier polyester ripstop backing.

Weight: 200 gsm

Abrasion: 500 cycles

Tear strength: 119/110 N

Waterproof

Ultra200TX

The best of both worlds – the abrasion resistance of Ultra with the increased stability and prolonged waterproof lifespan of a 3-layer laminate. The ultimate choice for long lasting frame packs!

200 denier Ultra face, 45° polyester Cross-ply and 70 denier polyester ripstop backing.

Polyester components are 100% recycled.

Weight: 200 gsm

Abrasion: 4400 cycles

Tear strength: 459 N warp/592 N weft

Waterproof

For most pockets waterproofing is not a concern and therefor non-laminated fabrics are used. They’re lighter, more supple and cheaper too.

Custom selection

The full breadth of fabrics and colors is available for you to pick and match when you order a custom pack. They are subject to availability.

UltraX

A higly technical fabric with both amazing properties and drawbacks. The face has a high content of UHMWPE which has great abrasion resistance. Perfect for simple, low weight, durable and waterproof packs. Not the best for more complex packs, especially with

200 denier face of 67% ultra high molecular weight polyethylene/UPE blended with 33% polyester, 45° Ultra cross-ply and waterproof 0,75mm polyester RUV-film.

Polyester components are 100% recycled.

Weight: 130 gsm

Abrasion: 4400 cycles

Tear strength: 459 N warp/592 N weft

Waterproof

Hybrid

The special coating adds incredible abrasion resistance. It has longer lasting waterproofing compared to the conceptually similar Liteskin fabric. A great option when a rugged pack outweighs a few grams saved.

Liquid crystal polymer coating, 400 denier face of nylon/polyester mix with 45° Cross-ply and 70 denier polyester ripstop backing.

Polyester components are 100% recycled.

Weight: 310 gsm

Abrasion: 15000 cycles

Tear strength: 166 N warp/151 N weft

Waterproof

Getting nerdy...

Properties like waterproofness, abrasion resistance, tensile strength, and tear resistance can be measured in a standardized way. Therefore, they tend to be the most common way fabrics are compared. However, they only hint at the longevity and performance of a fabric, as real-world usage differs wildly to the singular properties tested in isolation. Below is a chart of fabrics I offer with some common alternatives ranked by weight:

| Fabric | Weight (g/m2) | Abrasion (ASTM 3884 cycles) | Tear strength warp/weft avg (N) | Waterproof | Recycled components |

| DCFH50 | 102 | 500 | 191 | Yes | 0% |

| Ultra200 | 119 | 4400 | 516 | Yes | 40% |

| Ultragrid | 132 | 1100 | na | No | 90% |

| DCFH150 | 170 | 500 | 245 | Yes | 0% |

| RBC400 | 178 | 3000* | na | No | 90% |

| Ultrastretch | 186 | 3000 | na | No | 0% |

| EPX200 | 200 | 500 | 115 | Yes | 100% |

| VX21 | 210 | 500 | 93 | Yes | 0% |

| Ultra200TX | 210 | 4400 | 516 | Yes | 60% |

| Ultra400TX | 244 | 8800 | 689 | Yes | 55% |

| EPX400 | 304 | 3000 | 159 | Yes | 100% |

| EPX400HH | 310 | 15000 | 159 | Yes | 48% |

*based on fabrics with the same face

What can the numbers be used for?

In my experience, face fabric denier correlates better with real-world performance than most other metrics. Fabrics that score low for their face denier generally perform better in real world conditions than standardized tests would suggest. The opposite is also true.

Example: The ~200 denier polyester face of EPX/EPLX holds up better than the 50 denier polyester face of DCFH50, even though they score the same in abrasion testing. Ultra200 doesn’t perform an order of magnitude better than DCFH50, but it is still significantly stronger.

A note on Ultra

The amazing properties of UHMWPE used in Ultra are not without caveats, as it is very slippery and has a low-energy surface, meaning it makes for an unstable weave that is hard to bond. This is why Ultra has 1/3 polyester in the face. It stabilizes the weave and allows stronger bonding of the film, which further stabilizes the fabric as a whole. The film is not just for waterproofing, but also an integral part of the fabric. In real world conditions the film deteriorates and the integrity of the fabric gets compromised. I’ve had a much higher rate of fabric failure with UItra because of this and have discontinued the fabric as a result. EPLX performs just as good or even better at a lower price.

The new UltraX features a stabilizing X-grid and a thicker film improving the longevity. I’ve considered it but ultimately decided to stick with UltraTX as it has performed great and is worth the added weight for frame packs especially.

The outside is not everything - A note on waterproofing and laminates

While all the main fabrics are waterproof to over 200psi (140000mm HH!), packs made from them are not equal in waterproofing, especially over time.

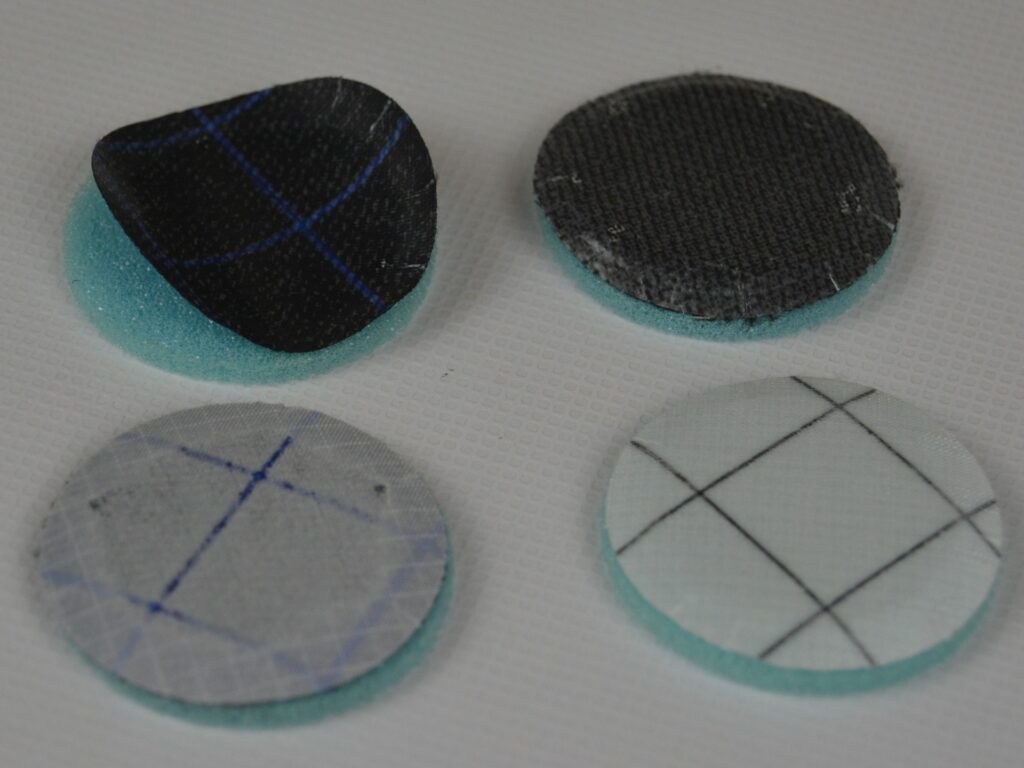

As I’m lucky enough to have a dad that develops sports clothing and tests fabric on the daily, I enlisted his help to test the internal abrasion resistance of my most used fabrics. He uses a Martindale tester, which can be loaded with a coarse woolen pad as an abrasive. This is a milder abrasive than the ASTM 3884 test in the chart above but perhaps more relevant as it more closely mimics what happens inside a pack. You can see more here.

Normally testing goes up to 50.000 cycles. The samples are pictured after 90.000 cycles. This was the point where you could see discernible wear on all but one sample.

EPLX (upper left) faired the best with no visible wear.

Ultra (upper right) had wear through the film only at the small creases created where the sample is gripped.

UltraTX (lower right) had very little wear, only visible on the cross-ply.

EPX (lower left) had wear all the way through the woven layer at multiple points along the cross-ply .

Both EPLX and Ultra have the same film. This version of UltraTX has a smoother weave internally than EPX.

The smooths surfaces handle textile abrasion very well. Packing your drybags, tent and clothing is not an issue. In real world use, multiple types of wear happen.

Film is much more susceptible to scratching and puncturing than the woven layers. Once it is even slightly compromised, it becomes more susceptible to wear and tear as witnessed on the Ultra sample.