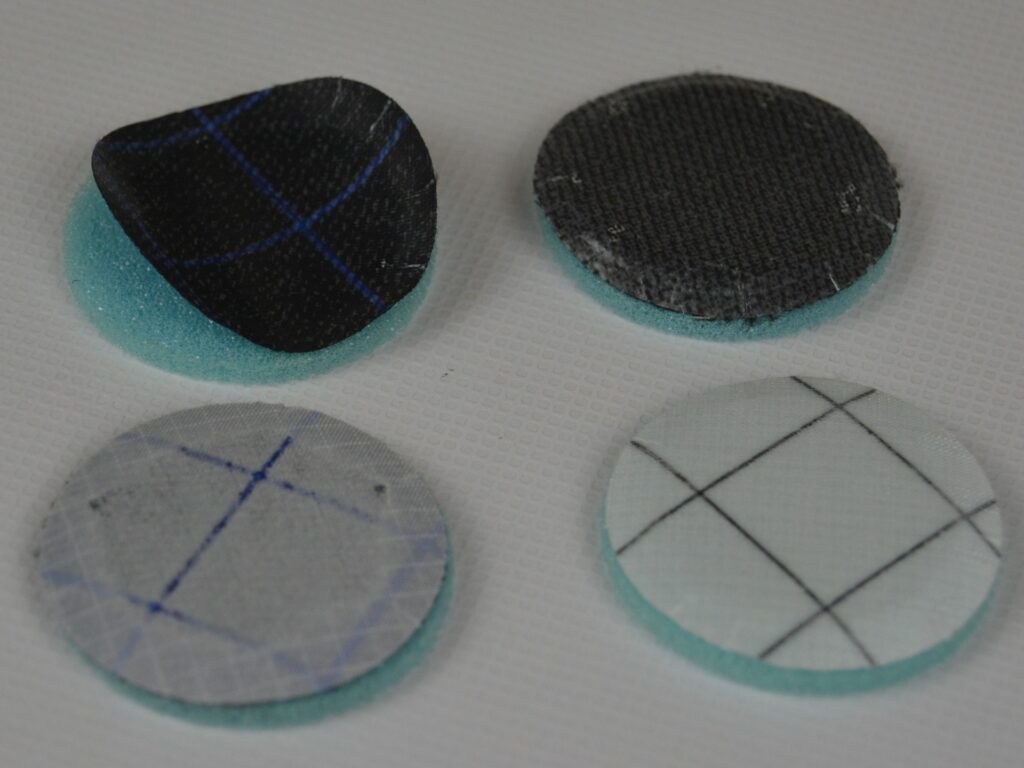

Your backpack is the thing you interact with the most while out hiking. Using one that suits your needs, both in terms of fit and features will greatly improve your experience.

How does it work?

1. Have a good idea of your needs. Think about what you’re missing from your current pack(s). If you’re not too sure, you can either contact me or use it as an excuse to go hiking some more until you find out 🙂

2. Have a look through the pack guide to make sense of the selection of base packs and suspension systems.

3. Look at the specific options available for the pack below. If you want further inspiration, take a look at my Instagram.

3. Fill out an order form. You’ll get a price and can order to get a spot in the production queue. If you want further customization than what the form offers, you can contact me. These changes carry a minimum custom charge of 200DKK.